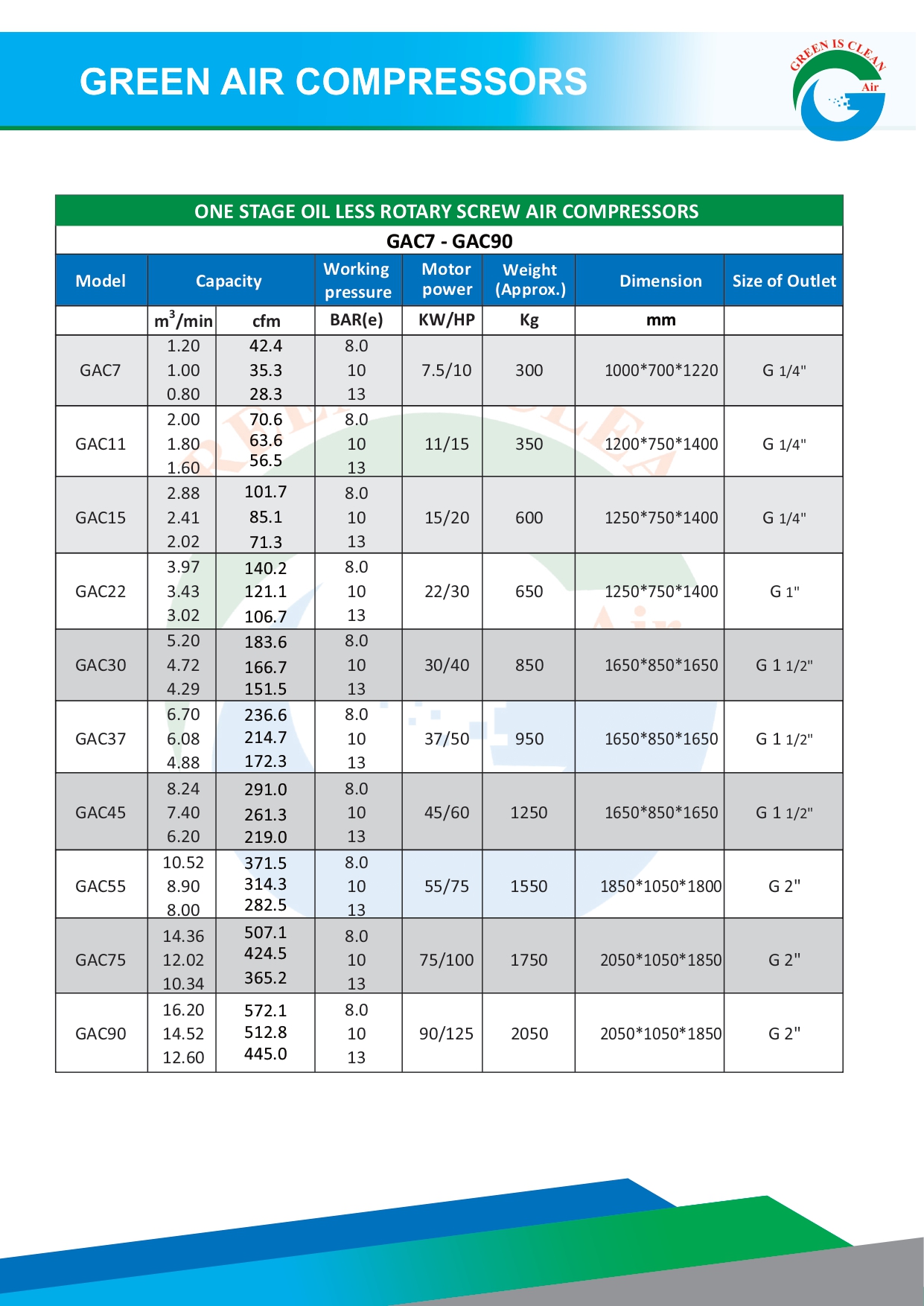

ONE STAGE OIL LESS ROTARY SCREW AIR COMPRESSORS

VARIABLE SPEED AIR COMPRESSOR:

Application

Heavy & light industry, mining, hydropower, seaport, engineering construction, oil and gas fields, railways, transportation, shipbuilding, energy, military industry, spaceflight, and other industries.

Features and Advantages of GREEN AIR COMPRESSORS Variable Speed Air Compressor

Intelligent Control System

Direct display of discharge temperature and pressure, operating frequency, current, power, and operating state. Real-time monitoring of discharge temperature and pressure, current, and frequency fluctuations.

The Latest Generation High-Efficiency Permanent Motor

Insulation grade F, protective grade IP55, suitable for harsh working conditions. No gearbox design, motor, and main rotor are directly connected through coupling, ensuring high transmission efficiency. Wide range of speed regulation and high precision in airflow regulation. The efficiency of the permanent magnet motor is 3%-5% higher than a regular motor, and it remains high even at reduced speeds.

The Latest Generation Super Stable Inverter

Constant pressure air supply with precise control within 0.01Mpa. Provides constant temperature air supply, generally set at 85℃, ensuring optimal oil lubrication and avoiding high-temperature shutdowns. No empty load, reducing energy consumption by 45%, and eliminating excess pressure. For each 0.1 MPa increase in compressor pressure, energy consumption rises by 7%. Vector air supply ensures production matches customer system air demand accurately.

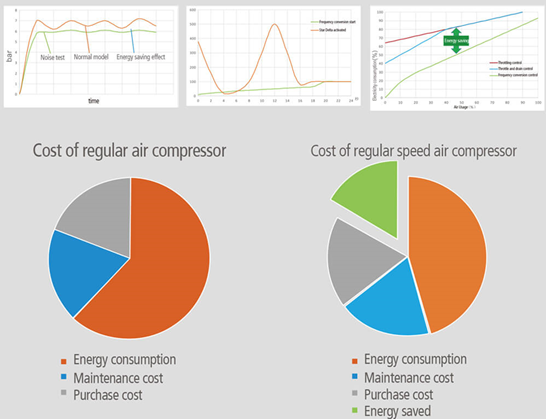

Wide Working Frequency Range To Save Energy

The frequency conversion ranges from 5% to 100%. The energy-saving effect is more pronounced when gas fluctuations are large, and the low-frequency running noise makes it suitable for various settings.

Small Start-up Impact

Utilizing a frequency conversion permanent magnet motor ensures a smooth start. The motor's starting current does not exceed the rated current, reducing impact on the power grid and mechanical wear, extending the main screw machine's service life.

Low Noise

The inverter provides a soft start with minimal impact, resulting in low start-up noise. Additionally, the PM VSD compressor operates at a lower frequency than fixed-speed compressors, significantly reducing mechanical noise.

Overall Energy Saving

Compared with a fixed-speed air compressor, the variable-speed air compressor offers significant energy savings.

Precise Pressure Control

The variable-speed air compressor responds quickly to pressure changes, adjusting the speed of the permanent magnet motor to maintain a pressure fluctuation range within ±0.1bar. This ensures stable pipe network pressure, providing the necessary air volume with optimal power and reducing excess energy loss.

Frequency Conversion Start-up

The variable-speed air compressor employs frequency conversion start-up, eliminating the peak current of star-delta start-up and enabling smooth starts. This reduces starting power, minimizes impact on the power grid and equipment, and lowers equipment operation noise.

Superior Variable Speed Control

Variable speed control outperforms conventional throttle control, with a broader adjustment range for the flow rate. Combined with a high-efficiency permanent magnet motor, the energy-saving effect is more significant at lower flow rates.

Life Cycle Cost Efficiency

Most of an air compressor's life cycle costs stem from electricity consumption. Power consumption is closely tied to on-site air planning. The variable-speed air compressor not only ensures smooth production but also significantly reduces electricity costs, achieving a win-win situation for the enterprise.