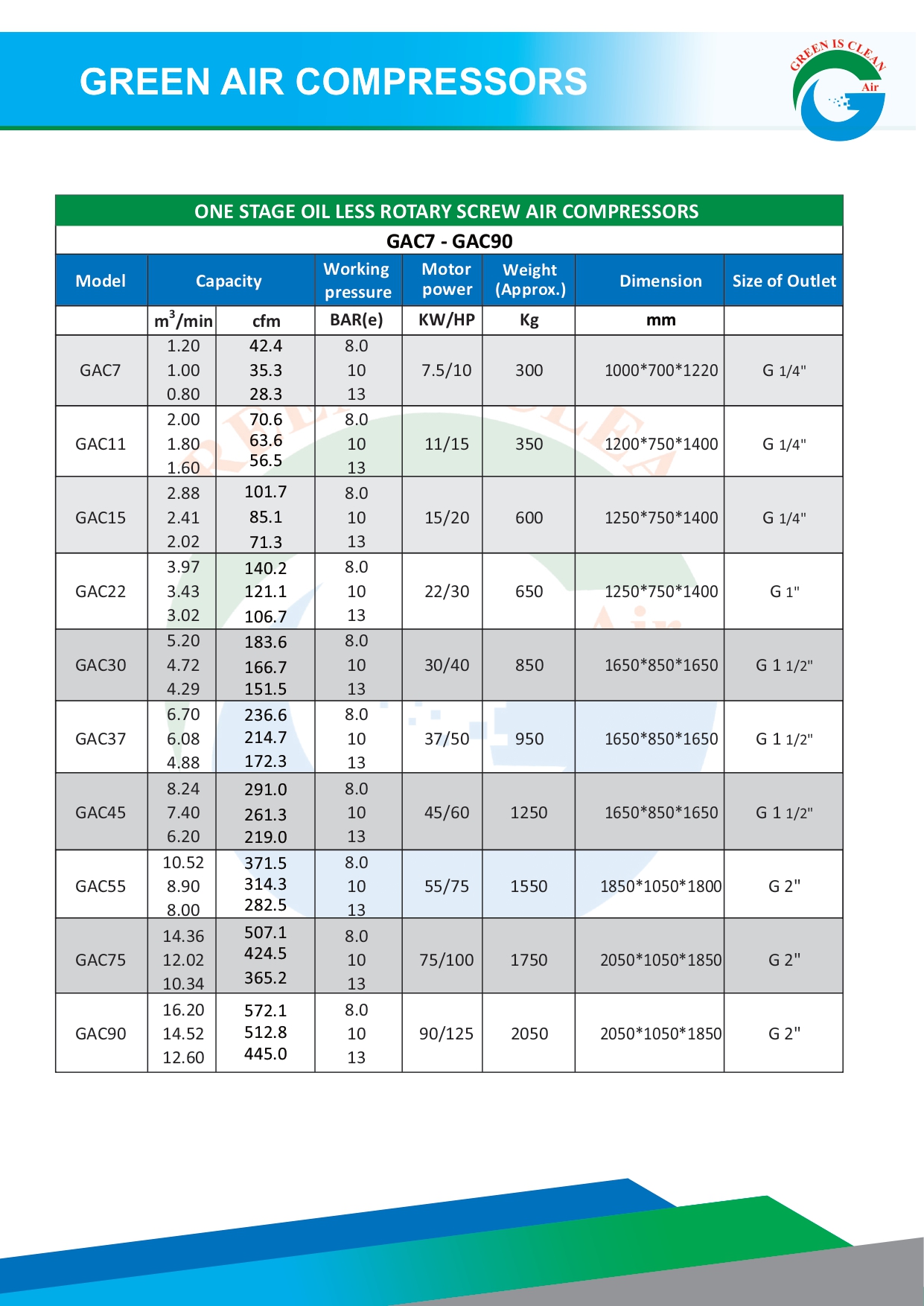

ONE STAGE OIL LESS ROTARY SCREW AIR COMPRESSORS

GAC7 - GAC90

Application:

Heavy & light industry, mining, hydropower, seaport, engineering construction, oil and gas fields, railways, transportation, shipbuilding, energy, military industry, spaceflight, and other industries.

Features and Advantages of GREEN AIR COMPRESSORS Fixed Speed Screw Air compressor:

Advanced High-Efficiency Air End:

Adopts industry-leading screw air end, high efficiency, and low rotating speed. With the third generation tooth type of rotor, cutting-edge geometric design-stable, reliable, energy-saving and long serviceFlexible Coupling Direct Drive:

Adopts direct connection structure without any loss, transmission efficiency is 100%, maintenance cost is low, disassemblies convenient, greatly save the downtime. Easy maintenance–air end maintenance only needs to disassemble the air end, motor maintenance only needs to disassemble the motor, do not affect each other.

Intelligent Microcomputer Control System:

Adopts intelligent control system to ensure fully automated intelligent operation, detect exhaust pressure, temperature, and other field data, and control the exhaust pressure within the preset pressure range through the intake valve, so as to output stable pressure.

Safe, Reliable, and Efficient Motor

Adopts unique low-speed motor, protection grade IP55, insulation grade F, suitable for bad working conditions. High balance precision, high speed running smoothly

Unique Heat Removal &Cooling System:

Adopts advanced design, harmonica radiator, effectively increase the heat dissipation area, run faster and smoother, and take away the heat of the machine in time. The heat exchange effect of the same area is 30% higher than that of the traditional cooler. Even in the Asia-Pacific region with high temperatures and high humidity, the normal operation of the unit can be guaranteed.

COOLER:

- The heat exchanger uses high-quality raw materials and a unique internal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

- The inner wall of the heat exchanger is treated with corrosion protection to increase the service life of the heat exchanger and increase the heat transfer effect.

- The radiator has passed the strict factory test, and the quality is reliable, which effectively prevents the high temperature of the air compressor and increases the service life of the machine

AIR END:

- Adopts the international top-level third-generation asymmetric wire twin-screw air end, adheres to the exquisite manufacturing process, adopts the peak high efficiency low-pressure, high-efficiency tooth shape and the axial air inlet design.

- Optimized flow channel design, with a large rotor, low speed, and high efficiency. Increased energy efficiency by 5% -15% compared to the second generation.

- Uses Swedish SKF heavy-duty bearings, double-lip lip shaft seal, durable and reliable. The bearing design life is 80,000-100,000 hours and the air end design life is about 200,000 hours.

CONTROLLER:

- Adopts PLC multi language control system, beautiful and intuitive interface, easy to operate function, operators can quickly and easily adjust the compressor.

- 14 protection functions such as overload protection, short circuit protection, reverse protection, low-temperature protection, high voltage protection, etc. to fully protect the unit.

- The advanced microcomputer control drive system realizes intelligent control, air volume variable speed control, automatic adjustment of load start and soft start. Intelligent dynamic control, dynamic display of the working status of each component of the compressor, visual pressure, temperature, current working curve, etc

- Large memory and equipped with printer interface; It can use computer remote monitoring or multiple linkage control between air compressors.

FAN:

- The fan uses a large fan design to effectively enhance the fan’s heat dissipation effect. The motor adopts a special internal design to adapt to harsh working conditions.

- The fan motor adopts special winding and high protection grade design to adapt to harsh working conditions.

- The fan is controlled by the controller to realize the automatic start and stop function, which effectively maintains the normal working temperature of the air compressor lubricant.

MOTOR:

- The motor uses high-performance motors of well-known brands. Permanent magnet synchronous motors (PM motors) use high-performance NdFeB permanent magnets which will not lose magnetism under 200 ° and their service life reaches as long as 15 years.

- The stator coil uses the frequency converter special halo-proof enameled wire, the insulation is outstanding and the service life is longer.

- The motor has the function of temperature protection. It also has a wide range of motor speed regulation, high precision, and a wide range of volume regulation. The reliability is significantly improved with small size, low noise, and large excess current.

- Protection grade IP55, insulation grade F, effectively protects the motor and increases the service life of the motor, the efficiency is 5%-7% higher than similar products.

INTAKE VALVE

- The intake valve is the core component to control the air intake of the air compressor.

- Adopting the world-famous brand air intake valve, it can automatically adjust its volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action, and long life consequently reducing operating costs.

OIL FILTER

- Adopts high-density filter material, the surface is treated with nano-electroplating.

- The filter element has uniform pore size, small filter resistance, large flux, strong interception ability, and long service life.

- High filtration accuracy effectively filters impurities in lubricating oil, prolongs the service life of the equipment.

AIR FILTER

Adopting a design with high dust holding capacity and low flow resistance, which can filter out tiny fixed particles in the air. The dust removal effect can reach 99.5%, ensuring the normal operation of the components of the system and extending the service life.

AIR-OIL SEPARATOR CORE

The high-quality air-oil separation element and gas-liquid filter element are equipped with advanced three-stage air-oil separation to keep the oil content below 3ppm to ensure the output of high-quality compressed air.

Fixed Speed Vs. Variable Speed Air Compressors

There are two kinds of industrial compressor machines. There are fixed-speed machines, and there are variable-speed machines. Both kinds of compressors have differences in how they operate.

Fixed Speed Screw Air Compressors

As its name clearly indicates, a fixed-speed air compressor operates by supplying a consistent — or fixed — voltage and frequency to its motor, which in turn drives its rotary screws at a consistent speed to draw in and pressurize the air. If your plant operates on a 24/7 basis without significant fluctuations in production cycles, then your energy consumption may be fairly consistent, and a fixed-speed air compressor might be a good choice.

If, however, your facility goes through daily, weekly, or even seasonal changes to its production outputs and subsequently has varying levels of air demands, then a fixed-speed air compressor will wind up using more energy and be somewhat wasteful over the course of its life cycle.

Variable-Speed Air Compressors

Unlike fixed-speed compressors, variable-speed air compressors have the added ability to vary the frequency they supply to their motors, which are then able to change the speed at which their rotary screws spin. This means depending on the air pressure needs of a given facility at any one time, a variable-speed air compressor can either slow down or speed up to meet those specific needs without wasting energy.

However, it must be mentioned that since variable-speed compressors have the ability to change their operational speeds, they are highly susceptible to any inconsistencies coming from their power source. That said, let’s put what we know together and see what the big picture tells us.

It should be clear that if you’re weighing the differences between fixed-speed and variable-speed air compressors, you need to look beyond the initial cost involved. Naturally, if your plant is prone to seasonal peaks in its production cycles or daily fluctuations in its air needs due to shifting differences, you’re going to want to look at how long it will take a variable-speed compressor to start saving you in lower energy costs when compared to a fixed-speed model. However, if your facility’s power source suffers from uncontrolled surges and drop-offs, then you may wind up paying a price for using a variable-speed compressor.

It’s also worth noting that for those who qualify for energy savings programs and tax incentives, there may be further financial benefits attached to installing a variable-speed compressor.